This category only includes cookies that ensures basic functionalities and security features of the website. Necessary cookies are absolutely essential for the website to function properly.

#Iso fits and tolerances chart iso

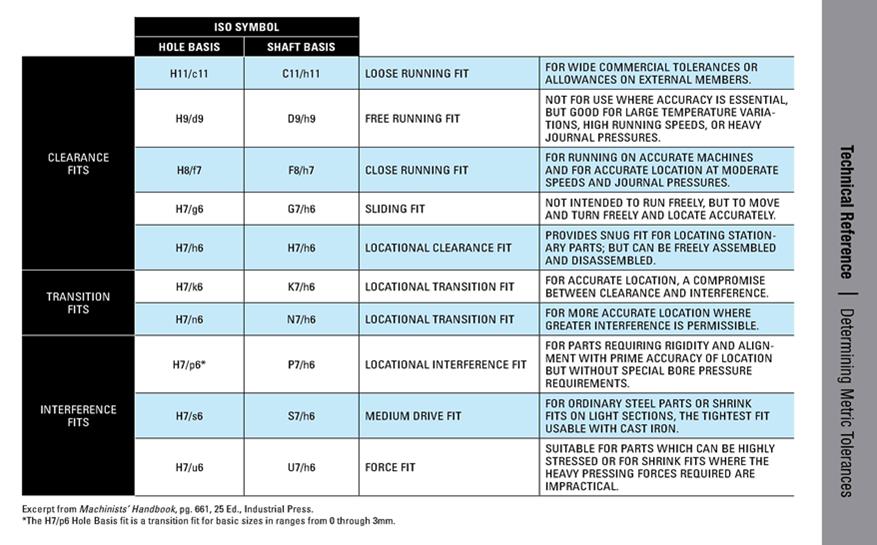

The chart below shows generally used industry standard tolerances, according to ISO 286-1 standard for hydraulic and pneumatic cylinders, presses. 8 – international tolerance grade number (IT#).H – fundamental deviation letter (fit, where capital letter refers to hole).That is why the fit is described by the basic size and the ISO fit symbol.įor example, a 250 mm cylinder bore with a tolerance class of H8, i.e. The tolerance class is combined with a basic size to determine the acceptable variation range. Actual size: the measure size of the finished part after machining.Basic size: the theoretical size used as a starting point for the application of tolerances.Nominal size: a dimension used to describe the general size.We have to distinguish three important sizes in case of parts: The ISO 286-1 and SIO 286-2 standards tolerance classes are commonly used to define the acceptable size range during the manufacturing, repair or refurbishment of the hydraulic and pneumatic cylinders. In fact, the variation sin dimensions of manufactured parts occur random within the tolerance range. Specification of the tolerances is important as well, as parts of the cylinders cannot be manufactured to exact dimensions, so acceptable range of variation must be defined. However hole basis systems are more frequently used.

Shaft Basis System: The shaft size is kept constant and the size of the hole is varied.Hole Basis System: The hole size is kept constant and the size of the shaft is varied.There are two different systems that can be used for obtaining any desired type of fit Fits and limits are standardized according to the International Standard ISO 286-1 and ISO 286-2, which are Geometrical Product Specification (GPS) standards. While the fit is the degree of tightness or looseness between two mating components to perform the defined function, the limits are the two extreme permissible sizes of the dimensions between, which actual size of dimension is contained. That is why the sizing and tolerancing of such components become very important. In such systems parts need to fit together with the required clearance/interference or with transition (mix of clearance and interference fit), in order to perform the desired role and function. Hydraulic and pneumatic cylinders are complex mechanical systems.

0 kommentar(er)

0 kommentar(er)